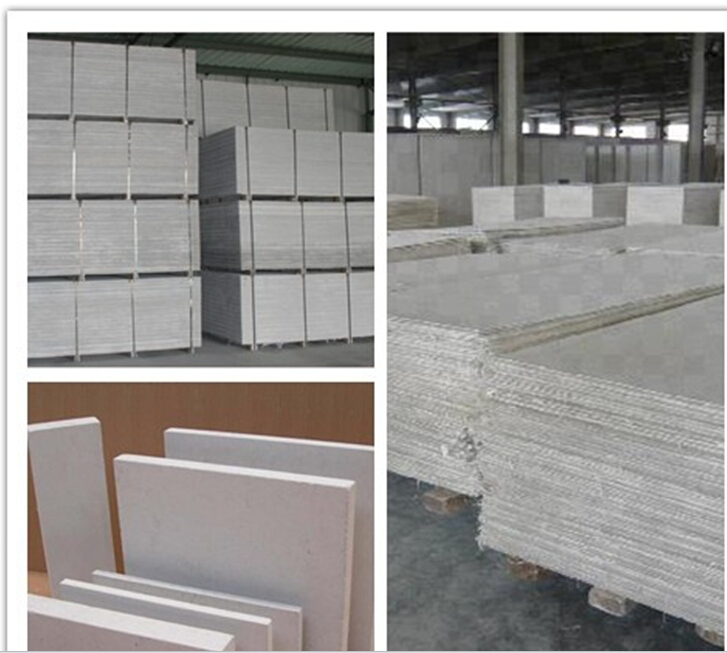

Fiber cement board is a new physical materials which use for

ceiling/internal decoration.

A. Raw material Processing System

Tank: cement tank, silica tank, lime tank, wollastonite tank,

bentonite tank, dust collecting tank, raw material tanks chosen

upon different requirements. Working principle: raw materials are

fed into tank and conveyed to weighing tank by screw conveyor, then

conveyed to slurry tank to be mixed.

Application of Board:

The board produced by our machine can be used for ceiling, wall

skirting, decorating of indoor wall and lining board for furniture.

And our board can replace three-ply board, five-ply board,

flakeboard, MDF (Medium Density Fiberboard ) and Gypsum Board.

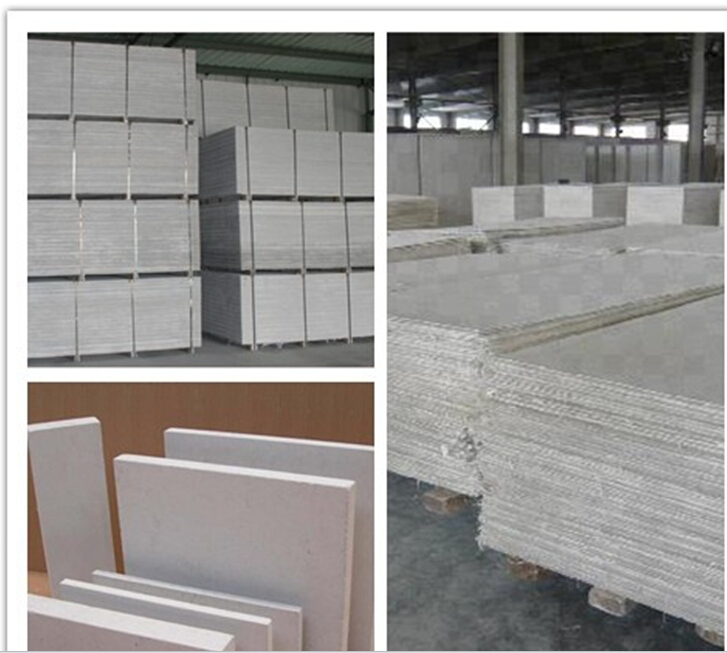

4. Board performance:

A. Oxygenic index%: >90

B. Level combustion: SO

C. Vertical combustion: SO

D. Water content rate: 10.9%

E. Capacity: 1.15g/cm3

F. Static bending intensity: 169.46Mpa

G. Density: T/ m3 1.13

H. Water resistance: Without chalking for 24 hours and there is no

change on surface

I. No “Three-wastes” (waste water, waste gas and waste residue), no

pollution and environmental protection

A. Raw material Processing System

Tank: cement tank, silica tank, lime tank, wollastonite tank,

bentonite tank, dust collecting tank, raw material tanks chosen

upon different requirements. Working principle: raw materials are

fed into tank and conveyed to weighing tank by screw conveyor, then

conveyed to slurry tank to be mixed.

B. Conveying System

Structure composition: belt conveyer and screw conveyer, composed

of belt, support, motor, screw blade, opening and close pipe

system. Working principle: convey raw material to destination by

motor drive.

C. Raw Material Weighing System

Structure composition: weighing tank, weight sensor, PLC and heavy

frame. Working principle: all raw materials are conveyed into

weighing tank, weight information is put into PLC after weight

sensor, when the reach designed weight information, the pneumatic

valve will open and feed raw material, and then valve closed when

get preset weight. Screw conveyor will transfer raw material into slurry tank, where raw material

is mixed. Scale weight tolerance: ±5kg